Have you ever seen the needle move if you own a sewing machine? Reciprocating describes the regular up-and-down or back-and-forth action of the hand. Valve opening and closing in IC (Internal Combustion) engines are regulated by a standout system.

CAM

A cam is a spinning part that makes direct contact with a follower to impart oscillating or reciprocating motion on the latter. This component’s primary function is to transmit linear signals from a rotating source to another element.

It’s a mechanical component consisting of either a revolving wheel (an electric wheel) or a shaft that impacts the lever at different places along its elliptical course. An engineer may utilize a cam in a steam hammer as a primary tooth to transmit power in bursts.

Follower

“Follower” refers to a mechanical component that responds to the cam’s motion. A spring-loaded mechanism or interacting with the cam’s surface is further possibilities. Its motion may be either uniform in speed or uniform in acceleration. With the aid of the follower motion, complex output motion is possible.

Cam Varieties According to Their Outline

It is possible to categorize the camera as:

- To achieve the desired motion of the follower, a flat plate or disc is cut and employed as a cam. The follower of this kind moves perpendicular to the cam’s axis of rotation.

- This cam has a cylindrical form and a groove carved into its surface; it is a cylindrical cam. The obedient one walks in the track. The follower’s path in this design is perpendicular to the cam’s axis of rotation.

- The cam is a wedge and operates with a sliding action called a wedge cam. When the camera pans left and right, so does the follower. In this case, cam and follower motion is perpendicular to one another.

Several Kinds of Followers

- The followers, like cam, come in various shapes, sizes, and movement styles.

- A knife-edge follower is one in which the follower’s part that makes contact with the cam is sharpened into a point. The sharp end quickly wears out the cam.

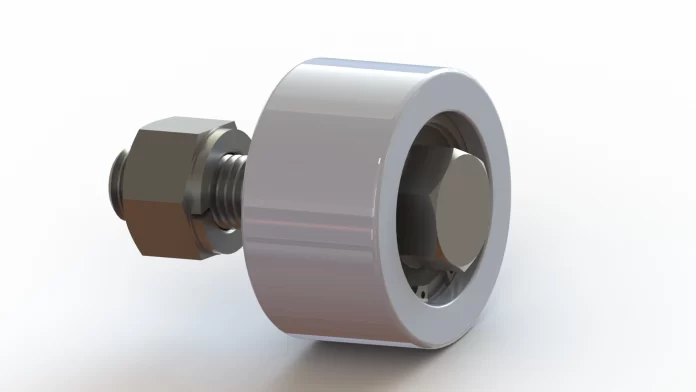

- Replacement for the flaws of knife-edge followers, roller followers is more reliable. Here, the follower touches the cam through a roller at its tip. It lessens the cam’s friction and wear and tear.

- The Basic Function of a Cam and Follower:

- Two regular forces, one in the X direction and one in the Y direction, cancel out the cocking moment that results from the presence of this force Fn.

- A friction force equal to twice the average power will oppose this vertical motion. If N represents the normal force, then this would be N. The follower encounters these two friction forces and the spring force during upward movement.

Conclusion

The cam follower mechanism is crucial because it drives a tiny machine part without jerks or stumbles. Cam and Follower mechanisms are used in the creation of central locks as well as standard lock systems.